|

The high altitude and access course took place in January, 2022. The training was led by Dion Tromp from Hi Angle Access and Rescue. Thank you to the South African National Biodiversity Institute for funding this training. Dion Tromp owns his own company and specialises in training courses for high altitude teams and focuses on high angle wilderness safety, and rescue training. In our case, allowing our teams to safely conduct alien clearing, while on ropes at height. Dion provides very important training to institutions, such as the SA Air Force and Working on Fire. We are grateful that he provided this specialised training to our alien clearing teams as he really is the best in the business. Dion is so calm and always has a smile on his face and it was lovely for the team to spend his Birthday with him. They all sang for him to celebrate with him. The purpose of the course. This course was designed for people who need to perform a task at height. In this case, our team needs to do alien clearing, in natural environments, such as on steeps slopes or vertical, mountain rock faces. When I walked into the shed with Linda, the conservancy's administrator, and saw our guys hanging on the ropes, we got goose bumps. We were impressed with this specialized training and how well Dion works with the trainees. The high angle training consisted of introduction to the course and theory as well as practical. The trainees learned how to inspect their equipment and perform the job as safely as possible. The participants also learned to rig simple anchors, ascent and descend. They mastered edge transition without high directional help, rope to rope transfers, maneuver through a re-anchor and maneuver through a deviation. The practical was done in our office shed and the rest in the Tradouw Pass. While doing the practical assessment in the Tradouw Pass, the ropes were tied to Dion’s car. The car was used as an anchor, and the trainees were able to do their exercise on the ropes. The training introduced a variety of rope access techniques, chosen specifically to improve the rescuer's ability to move through a static rope system. The trainees work at height, navigating rope obstacles and inspecting their equipment. We could see how interesting the training was, even our project manager, Ricardo, and quality control officer, Twakkie, tuned in to observe and familiarize themselves with the high-altitude training. When asked, the participants stated that they enjoyed the training, that it was challenging, and that they looked forward to each day. The training overall went well, so much so that we now have a very competent high-altitude team who are taking on the challenges of this important clearing work. Getting to work... We spoke with the Contractor (Marthinus Pick) who worked with the high-altitude team after the training. Marthinus Pick posed some questions to the team, such as the difficulties and high points of the high-altitude clearing. So, we turned it into a type of SWOT analysis (Strengths, Weakness, Opportunities, and threats). High- points (Strengths) They placed a high value on a sense of belonging to a group. When they work with the equipment and employ the proper methods, they feel good about it. They value the experience and the sense of accomplishment that comes with a successful day's work. They are also grateful because they are experiencing something that they had never considered doing before. Because the team had just returned from training and everything was still fresh, it was simple to apply the knowledge to the task. Challenges (Weakness) The terrain was challenging for them to navigate. It was also challenging to finish the task with enthusiasm and optimism. They expressed some difficulties adjusting from the clean, man made shed-structure that they had in the training to the realities of open rock faces where everything is a little more difficult to predict.The team did their best to apply the knowledge that they had gained from the training and the tasks that were assigned to them. Responsibilities (Opportunities) The team understands that they are each responsible for their own safety, as well as the safety of their team mates. They stated that they must ensure that their equipment is operational and that everything is in working order, and that it must be managed and monitored. Communication is also an important factor, and the team is aware that they must be able to communicate with one another on a regular basis to ensure that everything is still in order. Obtaining all of these skills presents great opportunities for each member to grow and perhaps move on to even greater things in life. This training has then opened them up to many new opportunities. What they believe can be improved (Threats) There are ways to improve by providing additional equipment for each member of the team so that more individuals can be on ropes at all times. It was noted that more attention must be paid to securing the anker because it causes the work to slow down if it is not in the proper place. As a team,there is a need to always plan carefully and follow through on what is agreed in the planning. Regardless of the obstacles, we are proud of the high altitude team's work thus far and look forward to seeing what they will achieve in the near future.

0 Comments

First Aid level 1 The first aid training was conducted by Verity Arendse from Coalition Training and Skills Development. The training took place in late October 2021 and was funded by the the Department of Forestry Fisheries and the Environment. What is First Aid? First aid is the provision of immediate assistance or care to a person who has become suddenly ill or injured. It is the care given by a person as soon as possible after an accident or illness, and a first aider is someone who has completed a training course in administering first aid at work and has a first aid certificate. Some content of the training The first aid training included theory as well as practical. The participants were made aware of the functions of the body for them to comprehend the body and how it functions. The instructor went into detail about the brain and heart (blood and circulation). The participants were educated on the various types of injuries that can occur and how to treat these injuries safely. CPR was performed as part of the practical assessment, with participants performing CPR on a doll. They also practiced bandaging a fracture or an injury. These drills also prepared them to remain calm if a colleague is injured or in trouble, to calm them down, and to communicate calmly to the injured as well as the rest of the team that may be stressed after an injury. Myths During the training, they also addressed some myths that are prevalent and should be avoided when treating an injury. For example, applying butter to a burn can make it difficult for the doctor to treat the burn and increase the risk of infection. It’s better to not apply butter at all. Cold water or ice is always preferable for a burn injury. When we believe these myths, we can exacerbate the situation. The participants worked through these myths throughout the training to understand what needs to be done and what one should not do during an injury. Food Yolanda Cupido and Adriana Miggels (contractors) made delicious food for the participants. The participants enjoyed the delicious food and looked forward to it as they attended the training each day. The First Aid training went very well, and you could see from afar that the participants enjoyed it. We were happy as we always are with the quality of training and the way our workers are being accommodated. Well done to all our participant that attended and did well in the training and are now trained first aiders! Herbicide Applicator Herbicide training was also conducted by Verity Arendse under Coalition Training and Skills development. The training took place in October 2021 and was funded by the the Department of Forestry Fisheries and the Environment. What is Herbicide? Herbicide is a mixture of a chemical designed to safely control unwanted weeds and invasive. The type of herbicide and the way that it is applied is crucial for the success of the product aswell as the health and safety of those using it. Content of the training? Care must be taken when using herbicide as desired plants could be harmed through negligent use of herbicide. And this was focused on as the participants were made aware of pesticides, herbicides, fertilizers, and colorants. The participants worked through plants listed as alien invasive species and the categories that they fall under such as category 1, category 2 and category 3. The participants discussed the difference between selective herbicides and non-selective herbicide. A selective herbicide affects some plants and not others and non-selective herbicides are toxic to all plants, for example, glyphosate. The participants needed to be aware of the right equipment for the herbicide application. The participants were taught how to mix the herbicide and the safety measures for applying the herbicide. Storage of herbicide During the practical, participants were shown the herbicide room at the conservancy office, where they could see the herbicide storage, read the stickers on the herbicide, and see the door with danger stickers on it. Aside from learning and discussing herbicide storage, the trainees were also made aware of herbicide transportation. The team discussed how the herbicide should be transported safely, as well as the extra-legal obligations associated with transporting the herbicide. The facilitator also went over some of the dangers of working with herbicides. Outdoors Following some theoretical work, the team went outside to conduct their practical. They went over the theory that they had learned, such as the Personal Protectove Equipment (PPE) that is required. They mixed the herbicide, according to the proper measurement that they had learnt, and they had the proper spray bottles and/or Knapjack to do the job. They enjoyed the training as the facilitator made jokes and made them laugh. We are now overjoyed to have our trained herbicide applicators, and we are confident that they will do us proud and keep themselves and the environment safe. Congratulations to everyone who took part. Health and safety in forestry

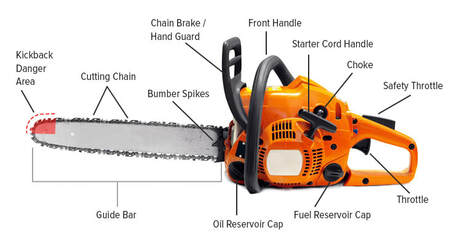

The instructor for health and safety was Lee-Roy Dirks, under Coalition Training and Skills Development. The health and safety training happened in December 2021 and was funded by the Department of Forestry Fisheries and the Environment. Toolbox Talks During health and safety training it was important to speak about the toolbox talks. These talks are health and safety briefs in the workplaces. The talks are used to address terrain, weather, or any other changing conditions in the veld. If there is an emergency, there is more clarity on what needs to be done and assurance that issues have been addressed to avoid accidents. PPE There are risks and hazards in forestry operations and some accidents can be fatal. Some accidents can be caused by machinery like chainsaws, others can be caused by adverse weather conditions. The health and safety representative is responsible for advising the team on how to be safe in dangerous situations. PPE (Personal protective equipment) is very important when working in forestry operations. The PPE is dependent on the kind of work a person does. For example, a chainsaw operator must wear gloves and an herbicide operator must wear a mask. Induction The team discussed how important worker induction is in forestry operations, in terms of safe working procedures. Induction covers a variety of topics, including emergency procedures, forestry hazards, hazard reporting, issue resolution processes, and more. At a later stage, safe working practices and procedures were discussed. Another important topic that was discussed was machine safety. The training went well, and we were glad that we could train another team of health and safety representatives. Over the last few months, we have hosted six different training courses that are essential to ensure that our teams work safely and effectively in the field. Over the next few weeks, we will share a blog a week for the different types of training that we have completed, starting with chainsaw and brushcutter training. These skills are important for alien clearing and fire break maintenance chainsaw TRAININGThe chainsaw and brush cutter training took place in late November and over 20 trainees attended. This training was funded by the South African National Biodiversity Institute. The week that the training took place was rainy and a bit chilly. While they were busy with chainsaw training, the trainees made jokes and laughed, while sharing stories in the field. Working with a chainsaw is a valuable skill to have, but it can be difficult at times and dangerous so there was always a serious element to every part of this training. However, these young men and women were eager to complete the course and obtain their qualification. Every trainee was geared up for this challenge. What is a chainsaw? A chainsaw is a power- driven cutting tool with a teeth set on a chain which moves around the edge of a blade. A chainsaw is a heavy machine that poses safety risks due to its external blades and cutting components; therefore, participants must pass the practical section of the course with a perfect score. Within the content of the work, the participants learned about the parts (external components) of the chainsaw. Facilitators The chainsaw training was led by Lesley Dick and Thembalethu Kamsela from Coalition Training and Skills Development. The participants wanted to know how to use a chainsaw as well as the safety procedures and requirements during the felling operation. Lesley went through the theory and assisted with the practical aspects and Themba also supported with theory and was mostly involved in the practical assessment. A chat with Themba, revealed that he was excited about the team who were committed to get the chainsaw qualification. “I’ll work with them when they do their practical’s, they’re still young and fit.’’ Content of the training Exhaust fumes and white finger disease were among the health risks discussed with the participants. White finger disease is a syndrome that affects the blood vessels, nerves, muscles, joints, and connective tissue of the hand, wrist, and arm. Employees who use handheld or hand guided power tools for more than a few hours per day are at risk of vibration white finger. The facilitator further discussed the consequences of an operator not wearing proper PPE (Personal Protective Equipment). The participants learned about transporting the chainsaw and the dangers of reactive forces. They were made aware of tree felling and the important aspects of it, for example, felling direction, felling quality and preparing for felling. They also learned about the maintenance of the chainsaws. The Protective Clothing The facilitators made it a point that the team, had all the right PPE to do the practical application. The following PPE is required when operating a chainsaw.

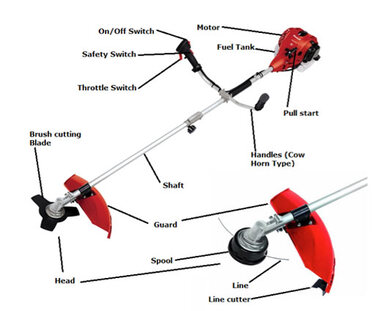

Outcomes of the Training When the trainees completed this specific training, they needed to be familiar with chainsaw parts and basic mechanics. They must be able to ensure safety when using a chainsaw. They had to be able to start and prepare the chainsaw and be able to fell trees using standard techniques. The importance of cleaning the chainsaw after use was also discussed. Lesley always emphasized the importance of keeping the chainsaw clean because chainsaws emit oil and grease. When the machine is turned off and cold, the oil gets stuck between the chain, guide bar, and sprocket and can shorten its life span; therefore, it must be thoroughly cleaned after each use. Routine maintenance, and knowing when to service chainsaw, or change chains or adjusting the tension of a chain was also covered. Other outcomes from the training were that trainees must be able to communicate with the right chainsaw linguistic to ensure safety during operation. The chainsaw course went very well, and the participants reaped the benefit of working hard to pass the course. They are now qualified chainsaw operators. We have great confidence in them, as they are now officially competent. brushcutter TRAININGThe brush cutter training was also coordinated by Coalition Training and Skills Development and funded by the South African National Biodiversity Institute. Brushcutter training is vitally important for fire break maintenance. Siyabulela Xaki was the person in charge of the training and the participants completed theory and practical components. Siyabulela was good with the trainees. He made jokes at times but when it was time to work, it was time to work! What is a brush cutter? A brush cutter is a powered garden or agricultural tool used to trim weeds, small trees, and other foliage that a lawn mower or rotary mower cannot reach. For specific applications, various blades or trimmer heads can be attached to the machine, which is powered by a unit held close to the body. A brush cutter is classified as a heavy machine which poses safety risks due to their external blades and cutting components and it is therefore mandatory for the trainees to pass the practical 100% to ensure the facilitator that the participants will not be at risk when operating the specific machinery. Like the chainsaw training, the brush cutter was divided into two sections which was the theory and the practical. With the theory, we covered all the parts of the bush cutter, the dangers, and the disease that you might get when not using the proper PPE (Personal Protective Equipment). Safety First Safety is very important. PPE was one of the most important safety measures. PPE consists of a safety helmet, eye protection, leg protection, footwear, ear protection and gloves or mitts. Siyabulela made sure that every participant had PPE and was wearing their PPE when operating the brush cutter. Before starting the participants needed to go through the parts of the brush cutter, see if all is in good order and record if something is not and ensure that the brush cutter is safe to use. While operating a brush cutter the students were taught that a safe distance between two operators is 15 meters and Siyabulela made sure of this rule. The trainees were also shown how the refuelling works with the brush cutter and how to do so safely. The practical application was done at strawberry hill farm, and the participants learned how to switch on and off the brush cutter and operate it. They learned how to use the choke and the handles. They practiced how to change the brush cutter blades and nylon string. An interesting part for the trainees was to learn which blade is used for which vegetation. When the participants did the practical assessment, the operation switched from cutting grass to cutting younger trees (alien trees), and a different, stronger blade was used, instead of the nylon. Siyabulela joked that the one trainee did not want to give the others a chance to use the brush cutter. Everyone laughed because they knew how much fun cutting could be, once you have mastered the brush cutter. The brush cutter training went very well as well. We were overjoyed and had no reason to complain. We are grateful to Coalition Training and the funder, SANBI, for helping us to master this important skill. Thank you. |

AuthorGVB Conservancy Staff Archives

May 2024

Categories |

RSS Feed

RSS Feed