|

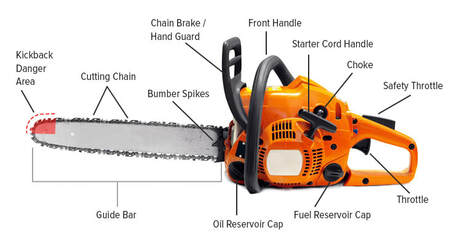

Over the last few months, we have hosted six different training courses that are essential to ensure that our teams work safely and effectively in the field. Over the next few weeks, we will share a blog a week for the different types of training that we have completed, starting with chainsaw and brushcutter training. These skills are important for alien clearing and fire break maintenance chainsaw TRAININGThe chainsaw and brush cutter training took place in late November and over 20 trainees attended. This training was funded by the South African National Biodiversity Institute. The week that the training took place was rainy and a bit chilly. While they were busy with chainsaw training, the trainees made jokes and laughed, while sharing stories in the field. Working with a chainsaw is a valuable skill to have, but it can be difficult at times and dangerous so there was always a serious element to every part of this training. However, these young men and women were eager to complete the course and obtain their qualification. Every trainee was geared up for this challenge. What is a chainsaw? A chainsaw is a power- driven cutting tool with a teeth set on a chain which moves around the edge of a blade. A chainsaw is a heavy machine that poses safety risks due to its external blades and cutting components; therefore, participants must pass the practical section of the course with a perfect score. Within the content of the work, the participants learned about the parts (external components) of the chainsaw. Facilitators The chainsaw training was led by Lesley Dick and Thembalethu Kamsela from Coalition Training and Skills Development. The participants wanted to know how to use a chainsaw as well as the safety procedures and requirements during the felling operation. Lesley went through the theory and assisted with the practical aspects and Themba also supported with theory and was mostly involved in the practical assessment. A chat with Themba, revealed that he was excited about the team who were committed to get the chainsaw qualification. “I’ll work with them when they do their practical’s, they’re still young and fit.’’ Content of the training Exhaust fumes and white finger disease were among the health risks discussed with the participants. White finger disease is a syndrome that affects the blood vessels, nerves, muscles, joints, and connective tissue of the hand, wrist, and arm. Employees who use handheld or hand guided power tools for more than a few hours per day are at risk of vibration white finger. The facilitator further discussed the consequences of an operator not wearing proper PPE (Personal Protective Equipment). The participants learned about transporting the chainsaw and the dangers of reactive forces. They were made aware of tree felling and the important aspects of it, for example, felling direction, felling quality and preparing for felling. They also learned about the maintenance of the chainsaws. The Protective Clothing The facilitators made it a point that the team, had all the right PPE to do the practical application. The following PPE is required when operating a chainsaw.

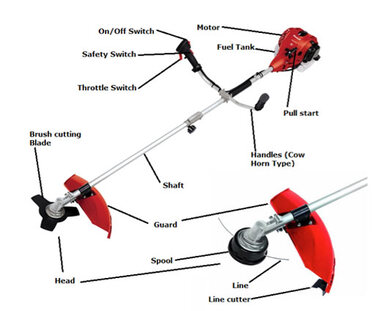

Outcomes of the Training When the trainees completed this specific training, they needed to be familiar with chainsaw parts and basic mechanics. They must be able to ensure safety when using a chainsaw. They had to be able to start and prepare the chainsaw and be able to fell trees using standard techniques. The importance of cleaning the chainsaw after use was also discussed. Lesley always emphasized the importance of keeping the chainsaw clean because chainsaws emit oil and grease. When the machine is turned off and cold, the oil gets stuck between the chain, guide bar, and sprocket and can shorten its life span; therefore, it must be thoroughly cleaned after each use. Routine maintenance, and knowing when to service chainsaw, or change chains or adjusting the tension of a chain was also covered. Other outcomes from the training were that trainees must be able to communicate with the right chainsaw linguistic to ensure safety during operation. The chainsaw course went very well, and the participants reaped the benefit of working hard to pass the course. They are now qualified chainsaw operators. We have great confidence in them, as they are now officially competent. brushcutter TRAININGThe brush cutter training was also coordinated by Coalition Training and Skills Development and funded by the South African National Biodiversity Institute. Brushcutter training is vitally important for fire break maintenance. Siyabulela Xaki was the person in charge of the training and the participants completed theory and practical components. Siyabulela was good with the trainees. He made jokes at times but when it was time to work, it was time to work! What is a brush cutter? A brush cutter is a powered garden or agricultural tool used to trim weeds, small trees, and other foliage that a lawn mower or rotary mower cannot reach. For specific applications, various blades or trimmer heads can be attached to the machine, which is powered by a unit held close to the body. A brush cutter is classified as a heavy machine which poses safety risks due to their external blades and cutting components and it is therefore mandatory for the trainees to pass the practical 100% to ensure the facilitator that the participants will not be at risk when operating the specific machinery. Like the chainsaw training, the brush cutter was divided into two sections which was the theory and the practical. With the theory, we covered all the parts of the bush cutter, the dangers, and the disease that you might get when not using the proper PPE (Personal Protective Equipment). Safety First Safety is very important. PPE was one of the most important safety measures. PPE consists of a safety helmet, eye protection, leg protection, footwear, ear protection and gloves or mitts. Siyabulela made sure that every participant had PPE and was wearing their PPE when operating the brush cutter. Before starting the participants needed to go through the parts of the brush cutter, see if all is in good order and record if something is not and ensure that the brush cutter is safe to use. While operating a brush cutter the students were taught that a safe distance between two operators is 15 meters and Siyabulela made sure of this rule. The trainees were also shown how the refuelling works with the brush cutter and how to do so safely. The practical application was done at strawberry hill farm, and the participants learned how to switch on and off the brush cutter and operate it. They learned how to use the choke and the handles. They practiced how to change the brush cutter blades and nylon string. An interesting part for the trainees was to learn which blade is used for which vegetation. When the participants did the practical assessment, the operation switched from cutting grass to cutting younger trees (alien trees), and a different, stronger blade was used, instead of the nylon. Siyabulela joked that the one trainee did not want to give the others a chance to use the brush cutter. Everyone laughed because they knew how much fun cutting could be, once you have mastered the brush cutter. The brush cutter training went very well as well. We were overjoyed and had no reason to complain. We are grateful to Coalition Training and the funder, SANBI, for helping us to master this important skill. Thank you.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorGVB Conservancy Staff Archives

May 2024

Categories |

RSS Feed

RSS Feed